Today we are joined by Mike Manning (aka @datamanning on Twitter) and Renee Hansen as they travel through Nebraska, to discuss soil sampling.

Mike is an agronomic information advisor in the state of Nebraska. He’s a western Nebraska farm kid from the panhandle. Mike has been working closely with growers throughout most of Nebraska for the last eight years. He has a wide range of precision and agronomic experience.

If you are enjoying the show, tweet us using #PremierPodcast.

RENEE HANSEN: Welcome to the Premier Podcast. We’re traveling down the road in Nebraska here. I’m sitting here with Mike Manning, @DataManning on Twitter. We went to meet with some growers, and we’re getting to about that season where we can talk about grid soil sampling. So Mike, why don’t you just tell us of the benefits. Does it really pay to grid soil sample?

MIKE MANNING: Absolutely, and it really is the perfect time of the year to be thinking about grid soil sampling. We’re getting ready to put a bow on the crop for 2020. We’re starting to do some of that early harvest prep in Nebraska. We’re also getting finished up with some of our final irrigations in corn. We still have a little ways to go on beans. Now is the time to start thinking about our fall fertility plans.

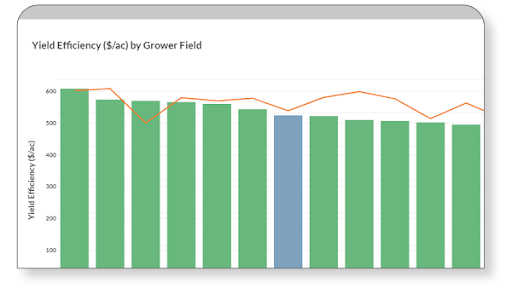

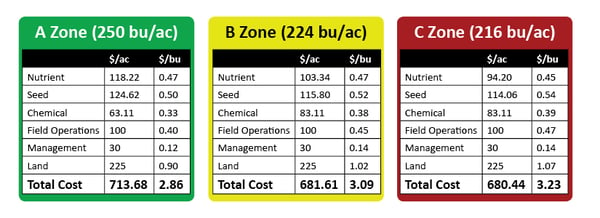

When I think of fall fertility, I think of grid soil sampling, or minimally, spatial soil sampling a field. Mainly though, we talk about grid soil sampling. Especially with what we do in Nebraska, and especially under irrigation, we look at a 2.5-acre grid sample. Sometimes at a higher resolution (1.1a, 1.5a), and sometimes at a wider resolution (3.3a, 4.4a). As we drive that combine across the field, we detect yield variability. Regardless of how table-top flat or how uniform a field appears, we don’t have uniform yield. We have yield variability across the field. That same concept applies to the soil fertility underneath the field.

What are our soil test values in the field? And, how do those soil test values change across the field?

RENEE HANSEN: What are you going to use that for, as the soil tests change across the field? How do you map that, and why is that so important?

MIKE MANNING: Bottom line, I really say the fundamental piece of precision ag, is a grid soil sample. But what do we use that grid sample for? Primary use number one: variable-rate application of our dry fertility products. We think of that as phosphorus, potassium, lime in acidic soils, and potentially some AMS or CalSul, & sulfur-type products if we’re trying to manage or mitigate other field issues. We’re really looking at variable-rate application of your dry fertilizer products. Then identifying where we need more fertility in the field. We also identify the areas where we need less, or perhaps no additional fertility at all in the field. It’s really about reallocating the fertilizer dollar to where it needs to go within the field.

RENEE HANSEN: We were talking to some growers today. Sometimes, they say, that other growers want to cut. They’re so focused on the bottom dollar, or with the markets the way they are today, that they need to cut somewhere. But the growers that we were talking to today, the ones that work with Premier Crop, they’re not focused on cutting on inputs. They think that they know that utilizing this grid sample really helps them build that foundation. So, can you talk a little bit more about building that foundation using the grid soil sample?

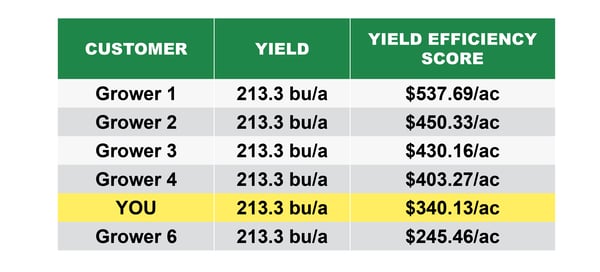

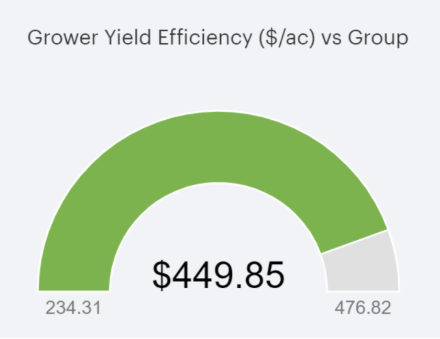

MIKE MANNING: You hit on a couple of really good points there. Bottom line, at the end of the day, what matters on the farm is profitability. Every grower in the world wants to produce their crop as efficiently as possible. They also want to spend as little money as possible to do that. But they need to do so without cutting any corners in fertility to produce a good crop. and produce it profitably. One of the easiest ways to do this is by variable-rate application of your fertility in a good, sound, agronomic manner.

Spatial soil sampling — in particular, grid sampling — has really been around for about 30 years. Early and widespread adoption more so came in the early 2000s period, combined with marrying it up to the yield data. Early on, and understandably so, a lot of growers that were burned, or had a bad experience with either grid sampling or zone sampling. This was largely due to two false premises. False premise number one: “the grid sample will show us the field variability and, Mr. Farmer, we’re going to make your field uniform.”

RENEE HANSEN: You and I have talked about that before, too, just how you want to make the field all green, and that’s just not realistic.

MIKE MANNING: That’s not realistic. It’s about identifying and managing where we need to add, where we need to reduce, where do we need to reallocate that fertilizer dollar?

False premise number two: “I’m going to save you money by grid sampling.”. We might save some money on our total fertilizer spend with a VR fertilizer spread. Pretty commonly though, we’re spending the same amount of money on fertilizer and, depending on what things we identify in that variability within that sample across that field, we might be spending more money. Again, I would say in the early days of grid sampling, there were guys that got burned on two false premises that were promised to them: “We’re going to make the field uniform”, and “I’m going to save you money.”. Very rarely is that ever the case.

One prominent exception would be acidic soils. From central Nebraska all the way to Indiana and Ohio, all the way across the corn belt, VR lime, 99.9% of the time will pay for that grid sample in year one. Instead of looking at a quarter section or an 80 or a 40 and saying, “I need to go apply two tons of lime because my composite sample says I have a pH problem.”, we can redirect that lime dollar where it is most needed, and hammer the areas that are really in tough shape. If we’re in a high pH situation or have an area of the field that needs no lime, and we go hit it with that area with the same two or three tons per acre, we may actually be hurting ourselves.

We also might not be applying enough lime in the really acidic areas to truly be mitigating the problem. It’s a win-win. A lot of times we reduce the total tons of lime we need, and there might be hotspots in the field that need six or seven tons of lime, while half of the field, or large areas of the field, might need zero lime whatsoever.

RENEE HANSEN: Just tell me a little bit, does Premier Crop have any skin in the game when it comes to grid soil sampling? Why do we promote it so much?

MIKE MANNING: The primary reason I promote it to my growers — universally, we promote it to our growers, and to our partners within Premier Crop — is because it’s sound agronomics. It is what makes sense to better manage your farm at a spatial level. As the field changes, how are we adjusting our management to account for those changes within the field?

It starts by having good data to make decisions, understanding that field variability exists, and we need to examine that variability. We need to understand that variability before we start to try to manage it or change things. At Premier Crop, we believe management zones make sense. We like to manage by zones. An advisor or grower may say, “Well, I have management zones. Why don’t we just variable-rate the fertility to those management zones.” I would say at a basic level, that’s an acceptable approach if you can verify that’s the right thing to do. But this approach doesn’t account for the variability within the management zone. It’s important to note there is fertility variability within each management zone.

So yes, I may have a 285-bushel yield goal in my A zone, but my soil fertility throughout that A zone is not uniform. And if I’m truly going to variable-rate my fertility to a yield goal, I also need to variable rate to the underlying soil test values within that zone.

In essence, what I am talking about here is we’re variable-rating the variable rate. We are varying our rate to that management zone by yield goal. And, we’re also varying our rate to the soil test variability from the grid soil sample, within that Management Zone (or sometimes a multi-sample zone sample within that zone).

There are a lot of methodologies and philosophies out there about how you go about creating management zones. One historic school of thought might be using the SSURGO maps, your NRCS and SCS soil maps. The soil type lines from the soil surveys. And that can be effective in some geographies. Largely however, in my experience in the state of Nebraska, our soil types are in that field, but those lines do not match up to where those soil type breaks happen.

The key reason for this discrepancy in Nebraska is that we have spent the last 60 years leveling ground so we can irrigate better. We’ve learned from some of our past mistakes. Those soil types exist in that field, but we’ve changed the soil dynamics since it was surveyed. In contrast, and I don’t have a specific example, there are a fair amount of places in Iowa where the soil type lines are darn near to the ‘T’. I’m sure some of my Iowa colleagues would disagree and say, “No, they’re way off on this county and this county.” But I’ve seen maps that match up to the line.

Back from the Nebraska perspective, even where we do have good soil type lines or we have another dataset, such as EM mapping or EC mapping, that maybe confirms those soil type lines, we don’t see a correlation to yield to those soil types.

RENEE HANSEN: Take this all the way from beginning to end. We prefer to have a grid soil sample because it is such deep data. You get so much more information from the field. And then you were talking about how you can variable-rate all of your nutrients. Then, you’re going to also variable-rate your seeding, and then talk about the yield. I mean why are all of those layers so important?

MIKE MANNING: Because yield is not created equally. Our best areas of the field have probably historically been the best areas of the field. Our poorest areas of the field have probably been our poorest areas of the field. That’s how geology created them. That’s how soil formation created them. It’s also influenced by how long a piece of ground has been farmed, and how it’s been managed for the last 50, 100, 200 years, and the practices associated with how you go about your farming.

Tying it all together, again, I strongly encourage every single one of my growers to grid soil sample. If they’re not grid sampling, it’s not an absolute. You do not have to go do this. But if you really want to start putting the whole puzzle of soil fertility together, and really be able to look at the complexity of agronomy that happens within your fields, and begin to understand how to be more productive, and how to get more out of each field, and how to make each field more profitable, it starts by understanding what’s happening within the field with a grid soil sample.

RENEE HANSEN: I mean, when it comes down to it, a lot of people view Premier Crop as a data company, but we are highly focused on agronomics. You out in the field with your growers are highly focused on agronomics.

MIKE MANNING: Absolutely. It starts with soil. We build a crop from the ground up. We have to take care of the fundamentals, and we have to start with a good soil foundation under our feet to grow a productive crop.

There are a lot of products out there in the market that say “add this”, or “add that”. Don’t get me wrong. There are good products out there. There’s a lot of biologicals coming to the market. Some of those things have shown promise, and there’s definitely been some winners and losers. And I’m sure many of our growers have more than a few stories to share with that. If we don’t have good fundamental fertility underneath us as that strong foundation, we’re not going to produce a good crop to begin with. Regardless of what you throw out “on top”, is that additional product “X-Y-Z” supposed to result in “1-2-3”? Without a strong foundation, the “X-Y-Z” product afterwards is really just throwing your money away.

Grid soil sampling the first time can be scary. It can be daunting to some people, depending on change. Change can be difficult. If we’ve been composite sampling fields for years and years, and I’m putting out 100 pounds/acre of MAP and 50 pounds/acre of Potash, and that’s my dry fertility program at a flat rate. It can be eye-opening. It can be jarring, if you go pull a grid sample on that field for the first time because you’ve probably been noticing your yields slowly declining, or perhaps have plateaued, or are not increasing like we’re used to. You can’t quite get a finger on it, and you’re not quite sure what’s going on. In these cases, a lot of times, we’re mining out the best areas of the field. We have not been taking care of that the way we should be (crop nutrient removals).

Grid soil sampling is all about making sense of that. Reallocate the fertilizer dollar to where it needs to go. Sometimes this helps you save money. Other times, if a field has been neglected for 30, 40 years, or has just received a minimal flat rate for a really long time, there might be an eye-opening fertilizer bill the first few years. But it’s something that you can stair-step into. We’re not going to go in and try to fix everything in one shot. Let’s go for a walk first. Let’s work up to a jog, and then we’ll condition for a little bit. It’s not like trying to roll out of bed in the morning and go do the high jump.

One of the biggest things we say at Premier Crop is “identify limiting factors”. “What’s the number-one item that we need to address?”…when we get those grid sample results. What are one, two, or maybe three, major things that we really need to start working on and address if we’re talking about a field that’s really out of whack? The amount of dollars that get left on the table from flat-rate applications can be astronomical. We’re undoubtedly wasting fertilizer on the areas of the field that need little or none, and under-applying the areas that have been mined out.

Not necessarily devil’s advocate, but one example you mentioned earlier is “turning that entire map ‘green’ (making fertility uniform across the field). I work with a number of producers that have access to this “green mapmaker,” and that is manure. Manure is one piece that can sometimes be an objection to grid sampling. “Well, we manure. We have fertility levels through the roof.” That very well may be true. So, I want to offer what I call a few best management practices for manure.

Practice number one: if you have regular access to manure (or you’re a farmer feeder), move your manure around. Your manure has value. It pays to put wheels underneath your manure. Do not hit the home quarter every single time or whatever field is closest to the pen. It pays to spread it around.

Practice number two: Pull a grid sample after we have grown next year’s crop on that field. Again, if you have been hitting the same field year after year after year, let’s find another home for it. That fertility is going to be through the roof.

For growers that are heavy manure users — whether hog slurries, beef slurries, dried beef scrapings, etc. (each of these manure products has a different consistency, are typically applied at different times of the year, obviously, are applied at different rates, and carry different fertilizer values.). My best management practice for manure users is to pull a grid sample after we have grown next year’s crop on that field.

Say if we’re getting ready for a Fall 2020 manure application with dry beef lot manure in November, 2020, and I go apply 30 tons of manure. We grow a crop on it all of next year (typically corn), and after harvest next year, we go pull a grid sample on that. Naturally, I expect to see a lot of elevated (soil fertility) values in the field when we get the results. However, you’ll surprise yourself. You will have more holes, and inconsistencies out there than you probably thought.

Typically, we’re looking at 20 or 30 tons to the acre. We’re going to see those phosphorus values go through the roof. We typically pick up a lot of calcium. We pick up a lot of zinc. A pretty good shot of potassium, and hopefully not too many salts in the form of sodium. Say you’re at a 30-parts-per-million phosphorous field average, you might have a lot of values up to 100 parts per million, or 80 – 100 parts per million. But there could be some pretty good spreads between some of those points. You might still have a couple points at 45. You might still have a point down at 25 or 30, and the rest of the field is up at 80.

What guys and gals really need to be mindful of is manure is not a consistent product. Manure is a fantastic product that provides a lot of carbon back to the soil. But, it’s not a guaranteed fertilizer analysis that comes with an “N-P-K” label. Depending on the size of the stockpile, or the size of the barn, or the size of the lagoon you’re pumping out, I encourage you to take multiple manure samples throughout the season. If I’ve got a quarter-mile-long stockpile, I want three or four manure samples — good, consistent manure samples — out of that pile to get an idea of what I’m going to be receiving. Again, the bottom line is manure is not a consistent product.

RENEE HANSEN: It really starts with the foundation. We get started with a grid soil sample so we can ultimately make that crop as most profitable and efficient for the farmer as possible. Thanks for joining us today, Mike, as we’re headed down the road in Nebraska. Thanks for listening to the Premier Podcast, where everything agronomic is economic. Please subscribe, rate and review this podcast so we can continue to provide the best precision ag and analytic results for you.

________________________________________________________________________________________________

Free Resources:

- For more helpful tips and insight on all things data and agriculture, visit our blog at http://info.premiercrop.com/blog

- Curious about precision ag? Download our 5 Steps to Getting Started Guide: http://info.premiercrop.com/5-steps-guide

- Ready to cut through the bull? Download our No Bull Guide to Precision Ag: http://info.premiercrop.com/field-profitability-guide

- Podcast provided by Premier Crop Systems. Learn more about us at https://www.premiercrop.com