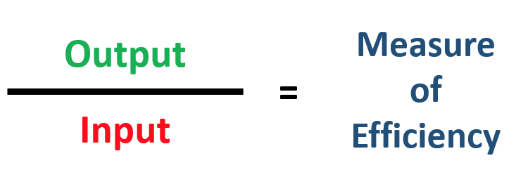

A quick Google search on the word efficient returns the following definition – achieving maximum productivity with minimum wasted effort or expense. I like to think of efficiency as a ratio, or fraction. Most often the input value of the equation is time or money. Efficiency is something almost everyone strives for in some aspect of their life. Think about different tasks you try to become more efficient at.

Here’s an everyday example of efficiency. My pickup’s gas tank holds 24 gallons and I can drive about 440 miles on one tank. My wife’s car has a gas tank capacity of 14 gallons, which gets her almost 480 miles of driving. One tank of gas in each vehicle results in only 40 miles difference in total output or miles traveled. However, when calculating efficiency these values equate to her vehicle being roughly twice as efficient as mine. If the capabilities (towing, hauling, etc.) of our two vehicles were the same it wouldn’t make sense to drive my pickup because the input expense is almost twice as much to return roughly the same output. This thought process can, and should, be applied to crop production.

Here’s an everyday example of efficiency. My pickup’s gas tank holds 24 gallons and I can drive about 440 miles on one tank. My wife’s car has a gas tank capacity of 14 gallons, which gets her almost 480 miles of driving. One tank of gas in each vehicle results in only 40 miles difference in total output or miles traveled. However, when calculating efficiency these values equate to her vehicle being roughly twice as efficient as mine. If the capabilities (towing, hauling, etc.) of our two vehicles were the same it wouldn’t make sense to drive my pickup because the input expense is almost twice as much to return roughly the same output. This thought process can, and should, be applied to crop production.

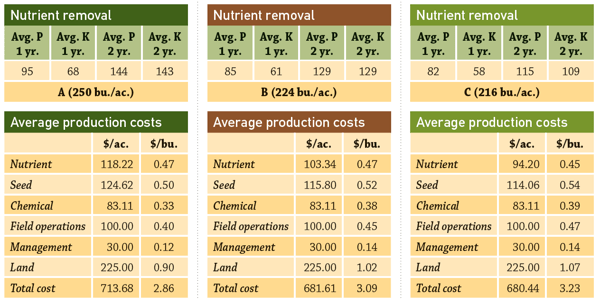

You rarely hear a farmer complain about being too efficient. However, production efficiency ($/bu.) is often overshadowed by one of its components: output. In farming output is synonymous with production, or yield. Historically, yield has been the basis for comparing hybrid performance, analyzing other agronomic factors, such as soil tests and application rates… and coffee shop conversations. Although yield is a critical component, it is only half of the equation when measuring efficiency. We must remember to examine the input side of the equation.

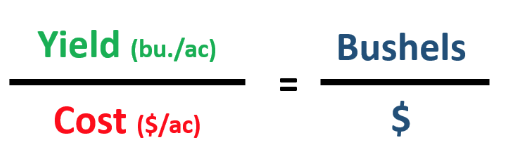

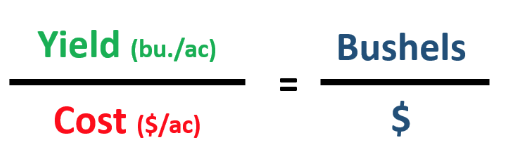

When completed the equation it reads as shown below.

I don’t know many farmers who are tracking the number of bushels produced per dollar invested. It isn’t a metric that can be easily related back to operational decision making. Here’s an example calculation: 235 bu/ac ÷ $700/ac = .34 bushels produced per dollar spent.

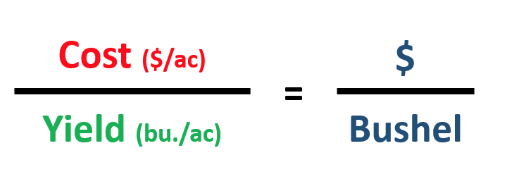

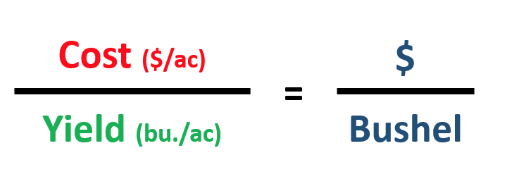

The result becomes more relevant when you flip the equation.

The measure of efficiency now equates to breakeven cost per bushel ($/bu.), or how many dollars it took to produce one bushel of grain. Here is an example with the same values from above: $700/ac ÷ 235 bu./ac = $2.98 / bu.

Cost per bushel produced is a metric that is easy to comprehend and is also actionable. Knowing your breakeven cost per bushel allows you to have greater confidence when making marketing decisions.

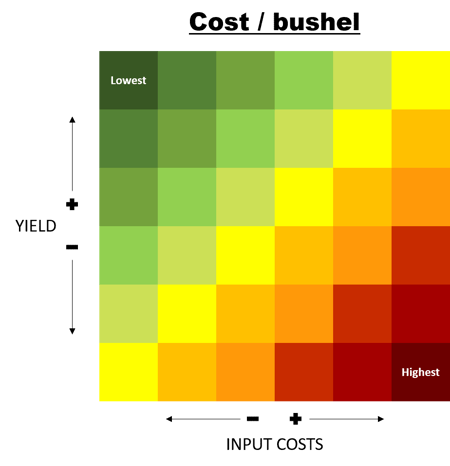

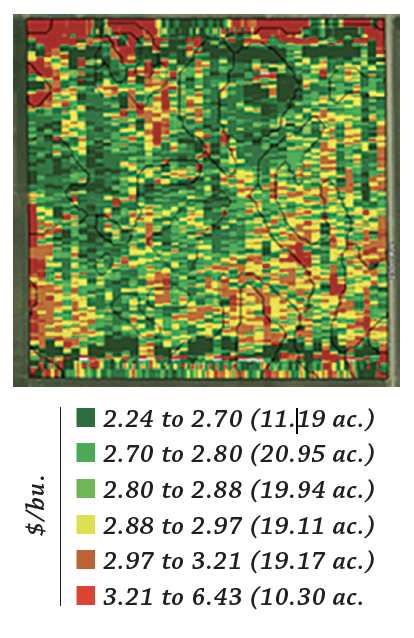

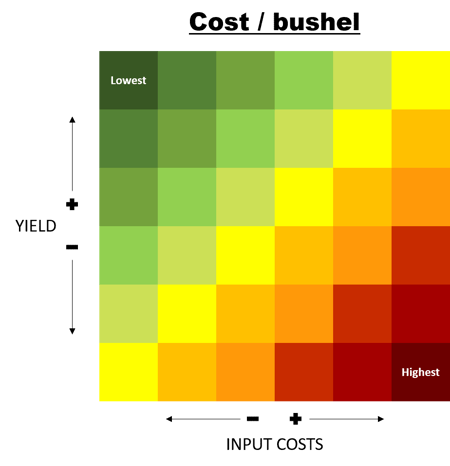

It’s important to understand that breakeven $/bu. changes within the field and that there are two ways to improve efficiency, or lower your breakeven $/bu.: 1) Reduce input expense 2) Increase yield.

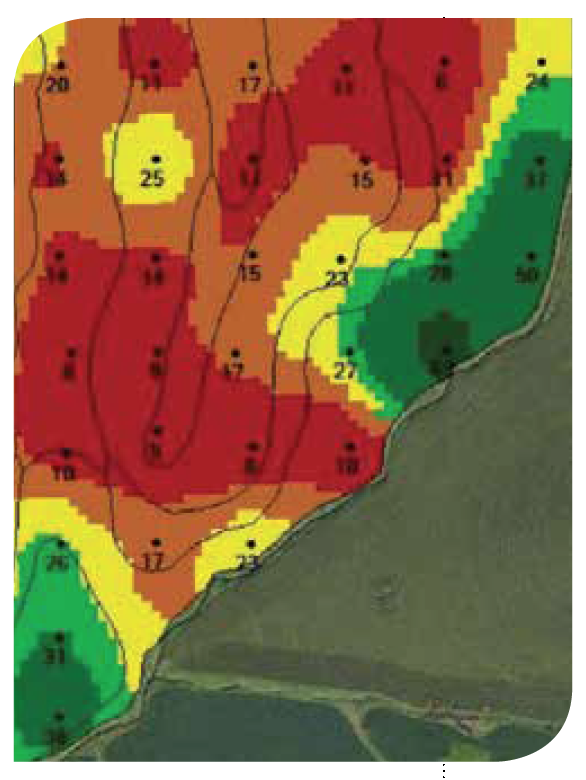

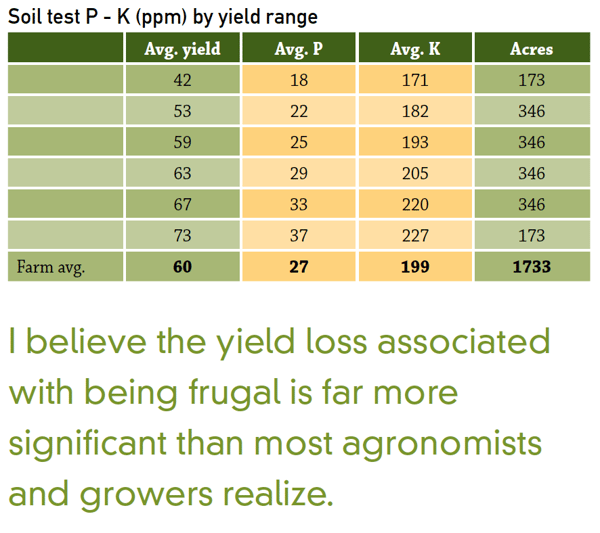

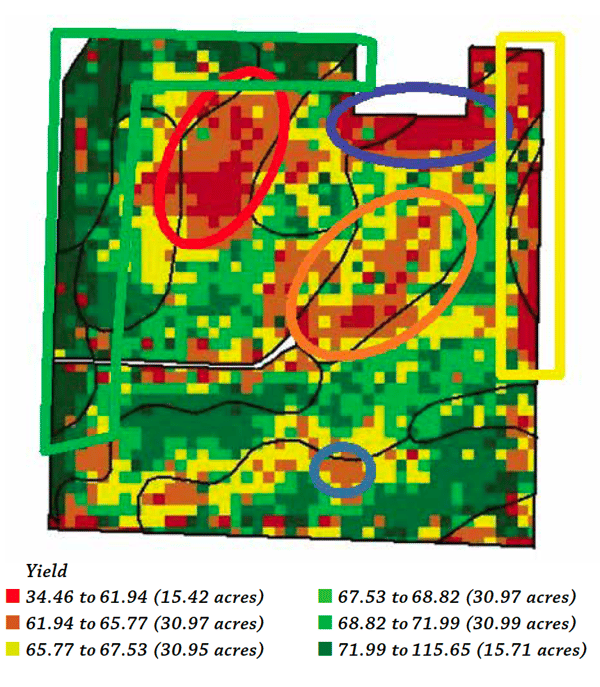

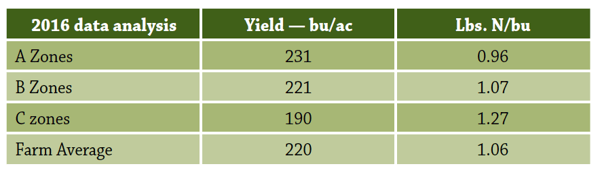

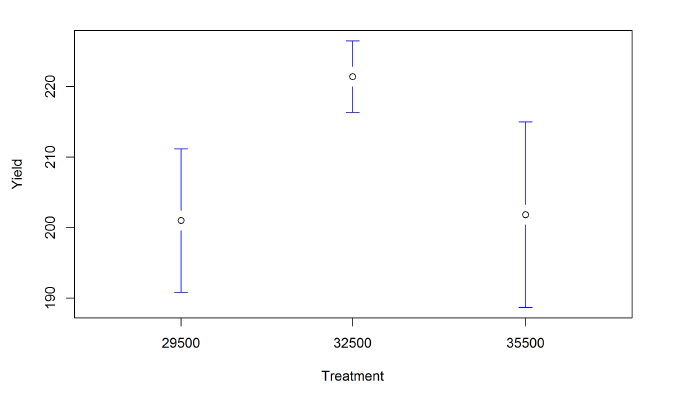

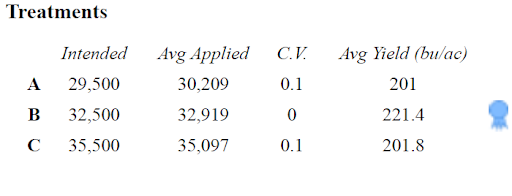

As a farmer, you’re able to control the input side of the equation, which directly affects output. To effectively lower your breakeven $/bu. and gain efficiency you must manage your input dollars spatially within fields. All fields have some degree of agronomic variability – yield, soil fertility, elevation, soil type, etc.

It doesn’t make sense to manage inputs at a flat rate across a field when trying to improve farm efficiency or lower your breakeven $/bu. For example, uniformly lowering your nitrogen rate across an entire field will reduce your input expense, but will limit your yield potential in ‘high productivity’ areas of the field due to the reduced rate. Conversely, excess nitrogen applied uniformly across the entire field will be wasted on areas with lower yield potential to begin with, dragging down efficiency.

Understanding and managing variability within each field is key to improving efficiency (lowering your breakeven $/bu.). Flat rate additions or reductions in inputs can have a significant impact on efficient production.

Understanding and managing variability within each field is key to improving efficiency (lowering your breakeven $/bu.). Flat rate additions or reductions in inputs can have a significant impact on efficient production.

People are always looking to improve everyday tasks to make their lives more efficient, it’s important to have that same mindset for farming. Remember that production (yield) is a key component of the efficiency equation, but knowing what it takes to achieve a specific level of production takes you to the next level of understanding profitability.

In part 2 of this series we’ll show you how to understand your profitability and see where you are leaving money on the table. You’ll learn how to make informed decisions and increase your margin.

Here’s an everyday example of efficiency. My pickup’s gas tank holds 24 gallons and I can drive about 440 miles on one tank. My wife’s car has a gas tank capacity of 14 gallons, which gets her almost 480 miles of driving. One tank of gas in each vehicle results in only 40 miles difference in total output or miles traveled. However, when calculating efficiency these values equate to her vehicle being roughly twice as efficient as mine. If the capabilities (towing, hauling, etc.) of our two vehicles were the same it wouldn’t make sense to drive my pickup because the input expense is almost twice as much to return roughly the same output. This thought process can, and should, be applied to crop production.

Here’s an everyday example of efficiency. My pickup’s gas tank holds 24 gallons and I can drive about 440 miles on one tank. My wife’s car has a gas tank capacity of 14 gallons, which gets her almost 480 miles of driving. One tank of gas in each vehicle results in only 40 miles difference in total output or miles traveled. However, when calculating efficiency these values equate to her vehicle being roughly twice as efficient as mine. If the capabilities (towing, hauling, etc.) of our two vehicles were the same it wouldn’t make sense to drive my pickup because the input expense is almost twice as much to return roughly the same output. This thought process can, and should, be applied to crop production.

Understanding and managing variability within each field is key to improving efficiency (

Understanding and managing variability within each field is key to improving efficiency (