There is a popular reminder used in crop production to spur a sense of urgency. It goes something like this: “You only get to plant a field 40 times in your farming lifetime. If you rotate crops, you might only get 20 chances to get it right with soybeans or corn.”

I’ve always loved those motivational do-it-now, make-the-most-of-every-day, you-can-rest-when-you-get-to-heaven-type messages, although I suspect psychologists would argue they are responsible for many of our “unbalanced lifestyles.”

Let’s assume you are motivated to get started using your agronomic data to make decisions. What do you do next? Spring planting is hopefully only days or weeks away; what is possible?

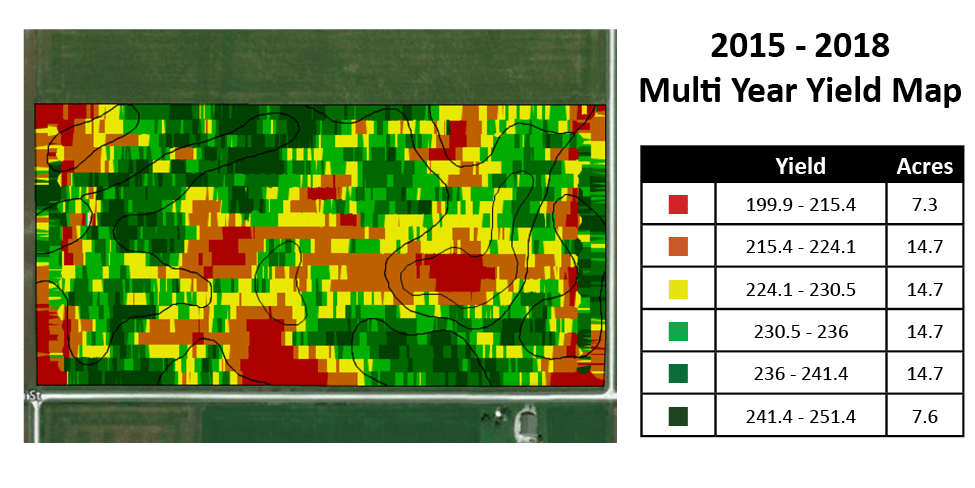

A great place to start using data to make decisions for the future is to gather all GPS data in an electronic form. Whether you use the data this fall, next spring or a couple of years from now, whenever you are ready – it’s just a click away. Paper maps are a start, but you can’t put them into the computer. Yield, soil tests, boundaries, any planting data you have or are going to gather – put it on a USB stick in the “raw data” format.

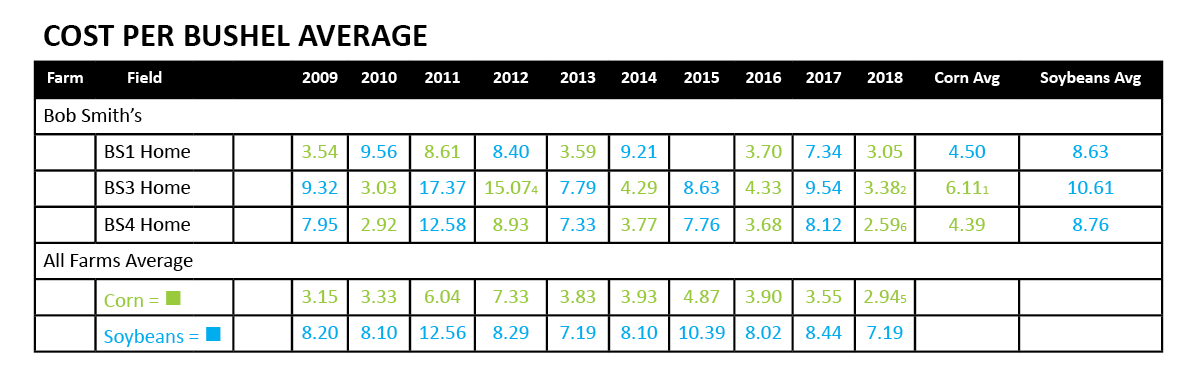

“We have been using a yield monitor for a long time and have saved data on a USB drive since 2006,” says Jim Krug, a grower from east-central Iowa. “Until recently, it has just stayed there on the stick, since we hadn’t been able to figure out how to use the information. The technologies are here; we have to utilize them. We wanted someone we could trust to sit down with us and go through the data so we can make important management decisions. Our agronomic advisor helped store and clean up our data, and from there, we now have the ability to capitalize on our investment by making the data work for us.”

Krug expects to see an ROI by just storing the data electronically over the years and then taking it to an advisor to go through it and analyze the meaning behind it all. The process can be easy if you have the data – especially in an electronic format.

Another way to cover your bases is to take notes about each field. Not all data can be collected on a monitor. Sometimes it’s just as easy to make a note. Organize a notebook with a page for each field and re-examine it with every field visit. After harvest, each field will have its own diary, which might help answer some of your production or management questions, or remind you what to ask an advisor.

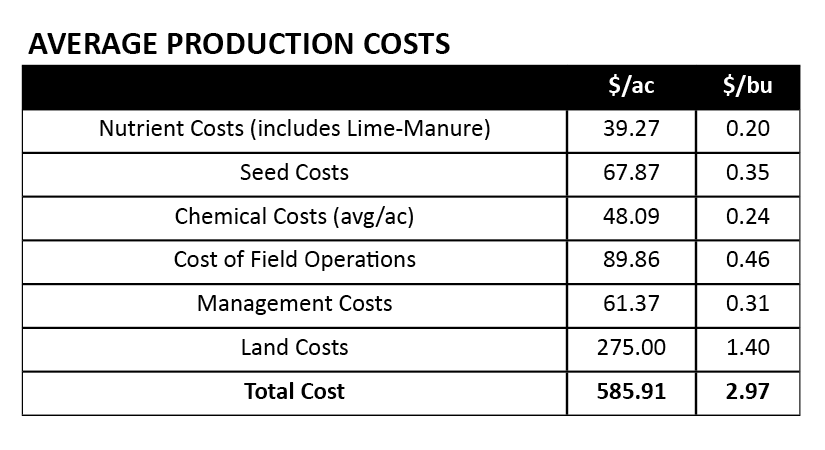

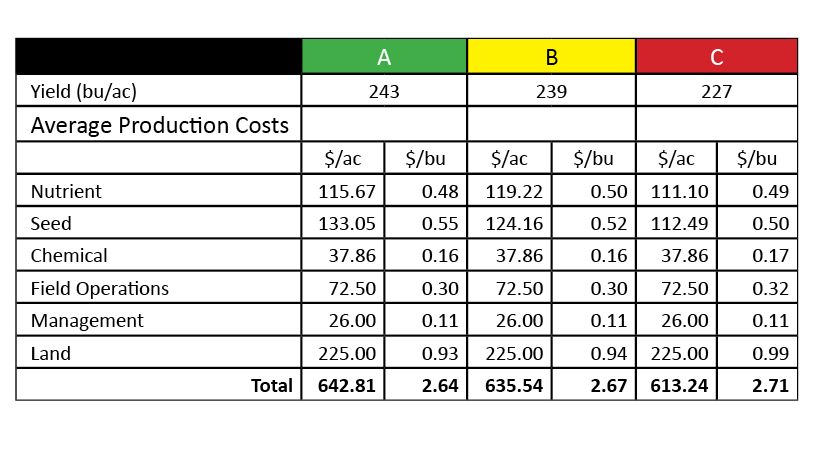

With every cop year, look back upon your successes and failures – always striving to become better, more profitable, more diversified. Using your data to make important agronomic decisions can be a great starting place to benchmark your own growth. So when your “40 chances,” are up, you can give yourself a big pat on the back.

GOT DATA?

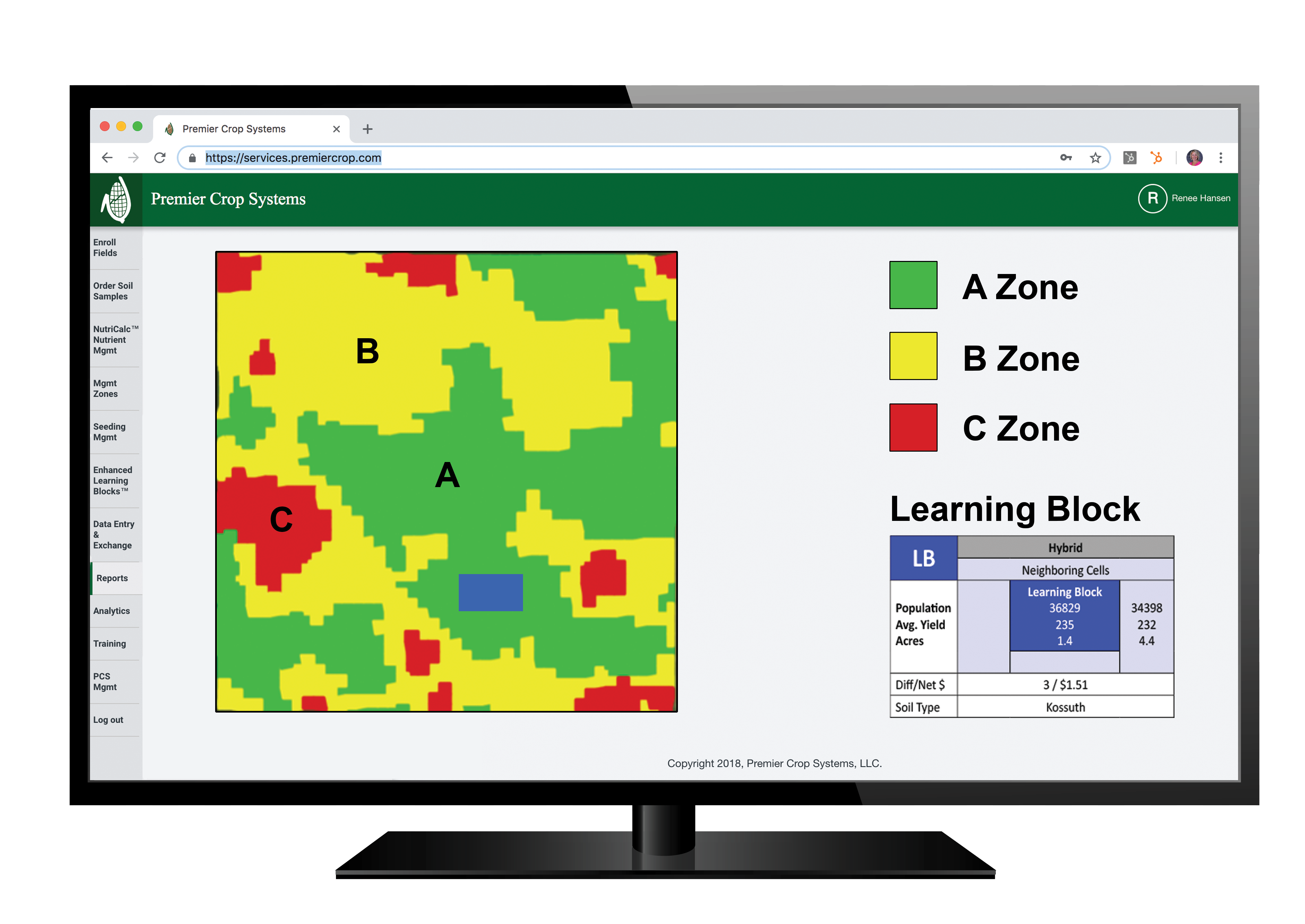

1. Seek out a local advisor to help you. Most of us don’t really want to become the expert in all aspects of our business. Just as you hire legal, accounting and marketing expertise, look for an advisor who shares your desire to use your data in decision-making.

2. Start collecting more data with your planting operation by logging hybrid and variety locations. Pre-loading your monitor with purchased seed umbers can make the process easier and is a great way to become familiar with the monitor’s buttons and screens again.

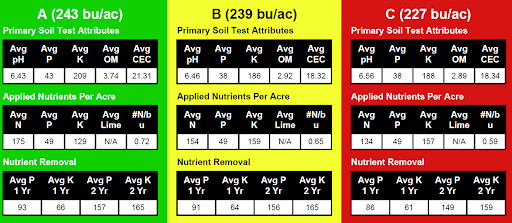

3. Order grid or zone soil sampling on some of your fields. Target fields with obvious variability or where you instinctively know you have production issues. Ask your advisor to explain the results.