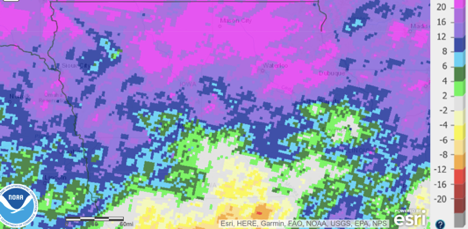

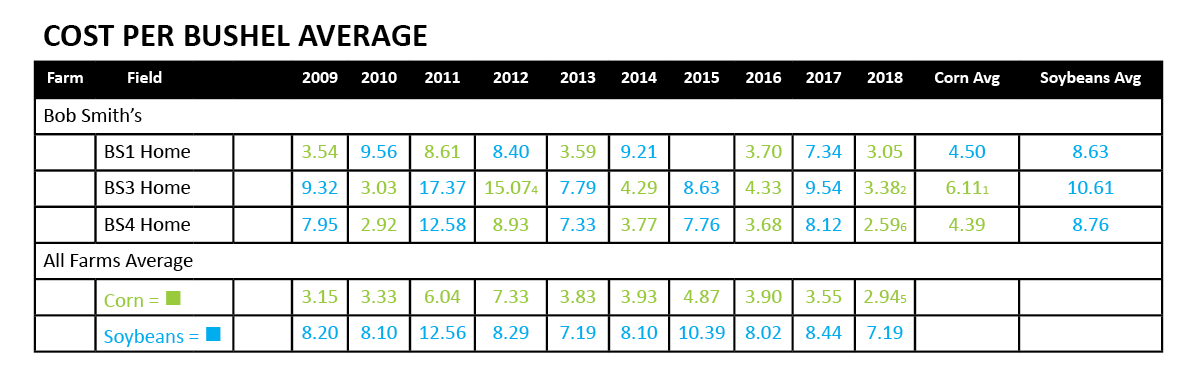

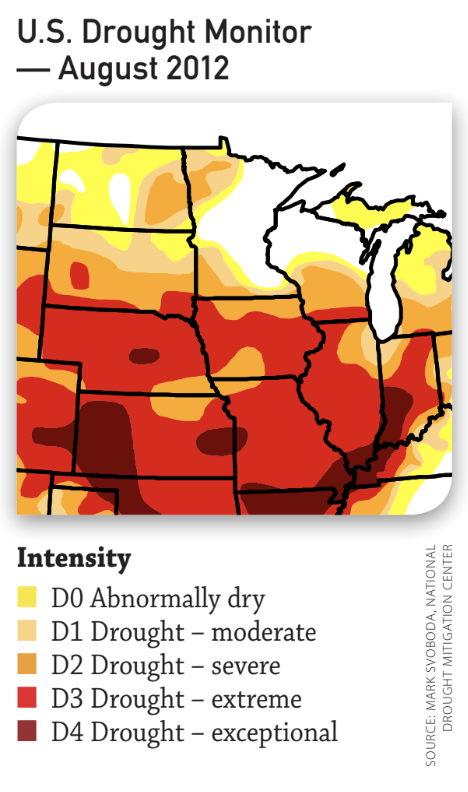

When we look back to 2012 it was historically dry, and 2013 started out wet and then turned dry. As some growers in the Midwest face yields below expectations, they’re finding new and different ways to learn from their data.

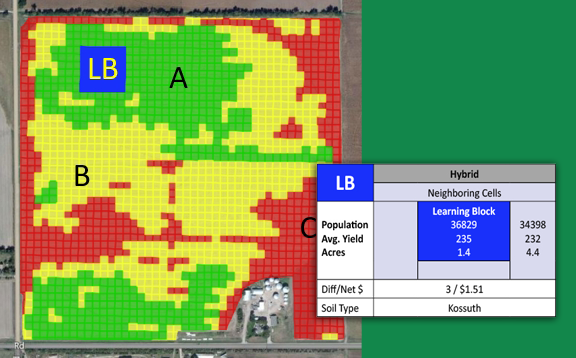

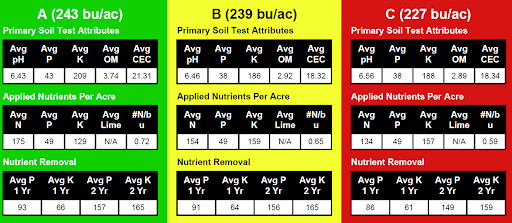

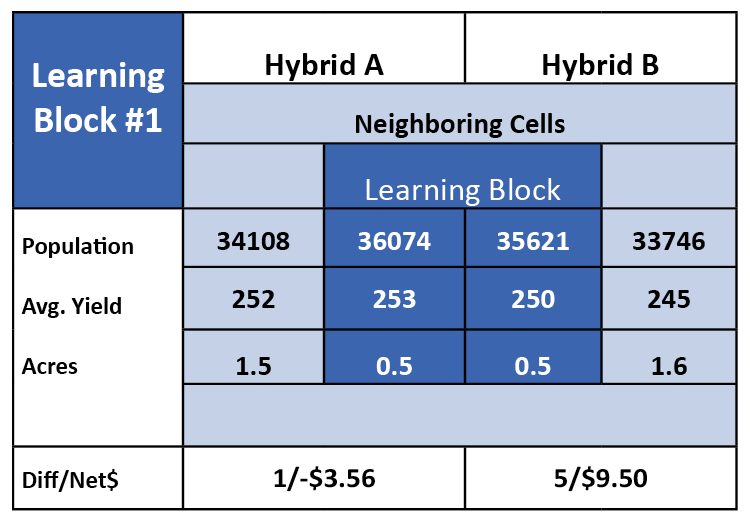

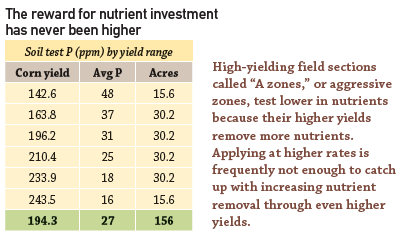

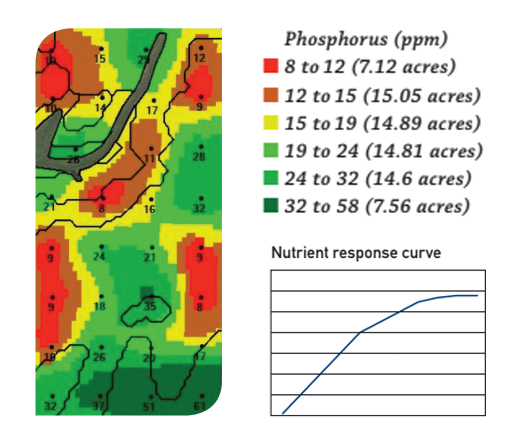

During the 2012 drought, north-central Iowa growers learned that they were being overly aggressive with plant populations on some lighter soils. This was a new trend for them, as abundant rainfall in previous years had masked these soils’ lower water-holding capacity. Since then, growers and advisors have paid more attention to those areas.

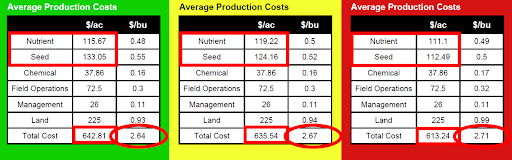

“We took the lemons of 2012’s lower production and made lemonade. We learned from the yield data and fine-tuned our management zones to apply more realistic seeding and nutrient rates on those lighter soils,” says Ben Rahe, a Premier Crop agronomic information advisor.

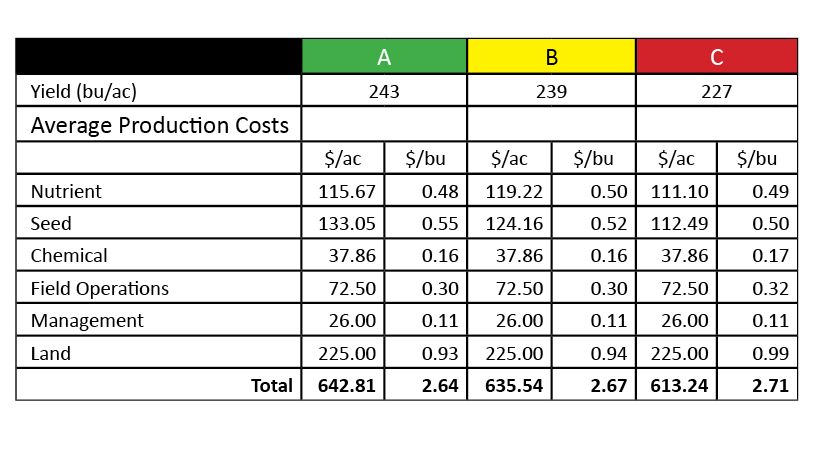

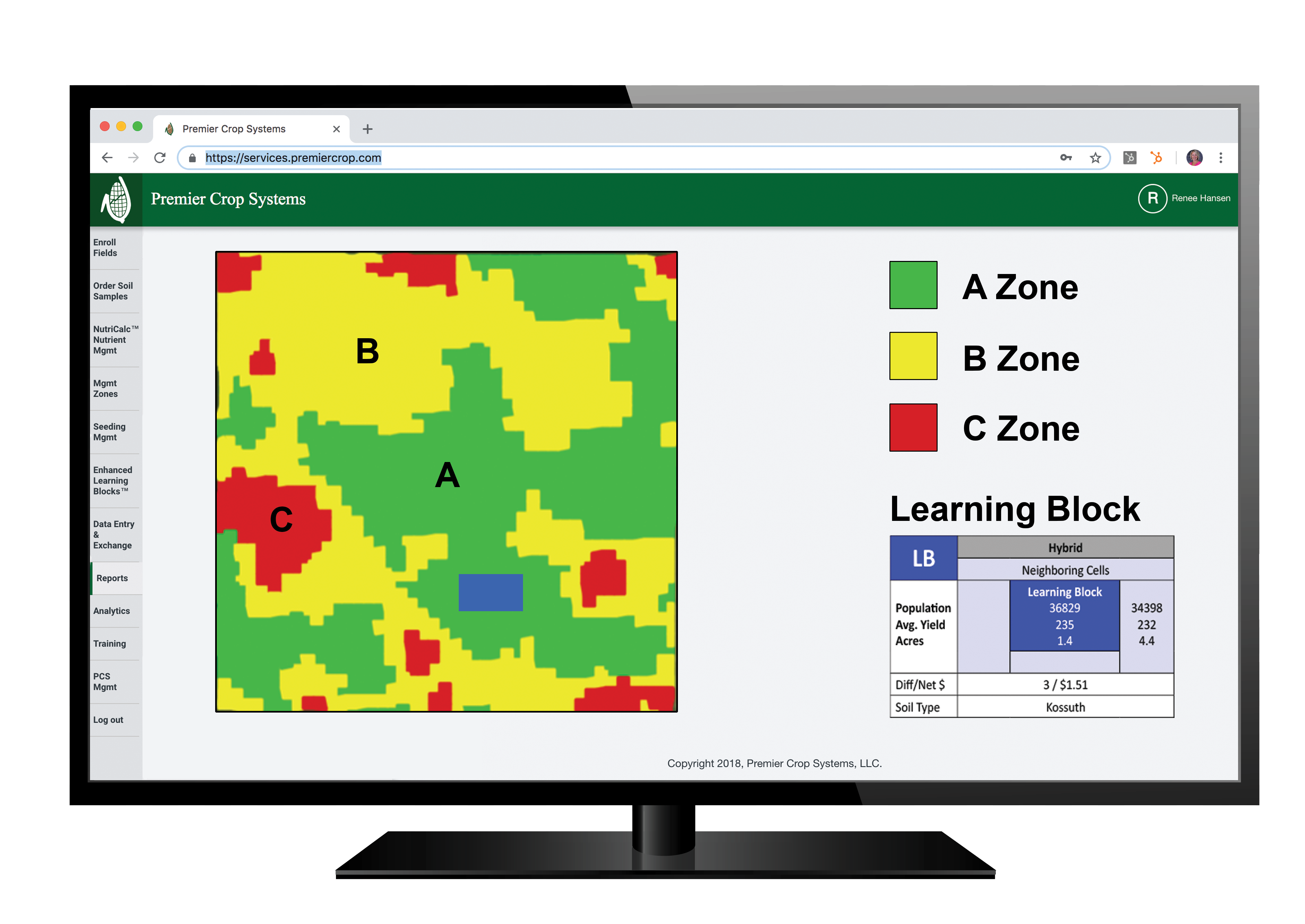

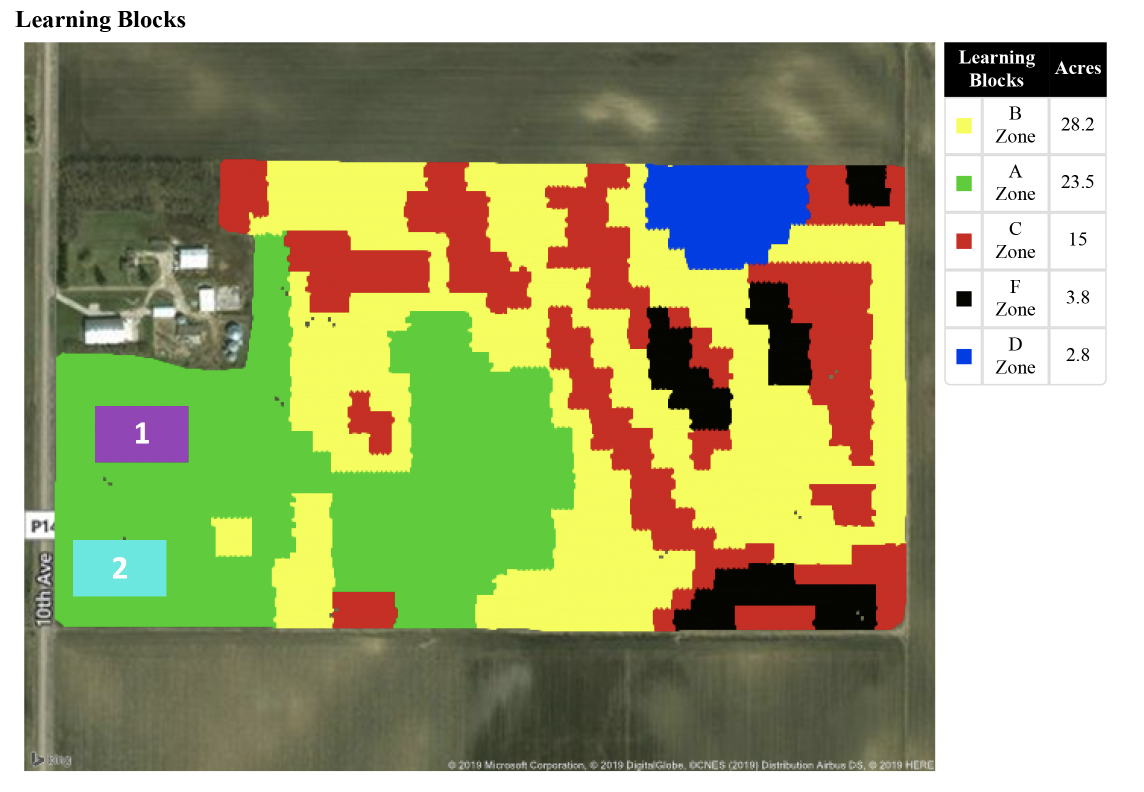

Northeast Indiana learned some valuable lessons from the 2012 drought, as well. “Even though yield information was so poor, we still had a lot to talk about with our growers about their management zones and what percentage of ground was in each A, B and C zone,” says Brian Warren, an agronomic advisor with ProTech Partners in northern Indiana.

Warren also found that with their 60-to-80 bushel crop in 2012, weather needed to be a bigger part of the equation. “If a bumper crop is roughly 200 bushels, and a grower averaged 80 bushels in 2012, we learned that 60% to 65% of what contributes to yield is variable, and the other 40% to 35% is contributed by management.”

Warren made lemonade by amending management zones for the future.

“Every crop season, we try to identify each field’s yield-limiting factors,” says Rahe. “in a wet spring/dry summer year like 2013, that may mean using yield data to more accurately determine where to invest in additional tile drainage. We make the best of extreme weather conditions by learning how a field response to them. We then discuss with the grower what can be done to fix those yield-robbing items.”

Having a geographically broad information source can help with getting through tough years. “Due to weather, I’ll have some growers with well-above-average yields and some growers with one of their lowest-yielding crops,” Rahe says. “The positive of this yield variability is that as an advisor, I can apply what I learn to both growers. For growers with low yields, I can show them anonymous information from those who were more fortunate. What may feel to them like a ‘lost’ year of information educated them. And for those with good yields, I provide them with a watch list for extreme-weather years.”

Extreme weather conditions can uncover variability that growers and advisors have never seen, reinforcing the value of field-by-field management and accentuating the importance of site-specific decision-making. Assessing your yield data with a trusted agronomic advisor improves your odds against Mother nature’s curveballs.

GOT DATA?

1. Capitalize on a relationship with an agronomic advisor who isn’t as geographically centered as you. Prepare five questions to ask him or her about what worked for other growers who didn’t suffer from adverse conditions.

2. Study the big yield-limiting factors – like drainage or managing drought-prone soils. What decisions can be made from those lessons learned?

Originally published in Corn and Soybean Digest December 2013.