“We have growers who tell us that we’re helping them with their economics, which helps convince their lender to give them the full operating line.”

Dan Frieberg

On this episode of the Premier Podcast, Dan Frieberg interviews the Farm 4 Profit show. Make sure to subscribe to their show at farm4profit.com. We hope you enjoy the conversation:

TANNER WINTERHOF: All right, welcome back to another Farm 4 Profit episode. This is Tanner Winterhof.

DAVID WHITAKER: And this is David Whitaker.

TANNER WINTERHOF: Dave, we got a little advice from a couple of peers as we put this podcast together that it would be helpful if we identified ourselves at the beginning of each episode. So, for a new listener, I’m Tanner. This is the voice of Tanner, and I’m a banker in central Iowa.

DAVID WHITAKER: And I’m David, and I am a farmland sales auctioneer and a real estate agent in central Iowa, as well.

TANNER WINTERHOF: So, thank you, new listeners, for joining us. We really appreciate you checking in. We’ve got a little bit of an interesting time this year. We started out with the coronavirus. We had some weather events. We’ve got inland hurricanes. We’ve got regular hurricanes. We’ve got droughts. Everything’s all storming together, but we’re going to focus on something a little bit more exciting today. We’re going to jump right into what’s working in ag. Don’t you think, Dave?

DAVID WHITAKER: I think so. We’ll just call it hashtag 2020.

TANNER WINTERHOF: That’s all we got.

DAVID WHITAKER: That’s what we’ll call it. We have a guest today. Who is our guest, Tanner?

TANNER WINTERHOF: We’ve got Dan Frieberg, and he is here to share with us a little bit about what’s working for ag in his company. A really neat background. He grew up on a farm in Iowa, graduated from Iowa State University. His career includes wholesale fertilizer sales, retail management. He also served as the CEO of the Iowa Fertilizer and Chemical Association, later the Agribusiness Association of Iowa, and other business consulting. One of his favorite beverages, if not the favorite beverage of Dan, can you believe this, is Diet Pepsi.

DAVID WHITAKER: There you go.

TANNER WINTERHOF: But what does this have to do with farming? What do you think?

DAVID WHITAKER: I tell you it has a lot to do with farming. So, Dan, tell us. I’m glad to see you’re an Iowa State grad. I’m glad to see you’re from Iowa. Anything we missed there, other than a good hair day and the Diet Pepsi thing?

DAN FRIEBERG: I think you got it nailed.

DAVID WHITAKER: Okay, great. Well, welcome Dan. Do you live currently in Iowa, still?

DAN FRIEBERG: Yep, just south of Des Moines.

DAVID WHITAKER: I got ya. And so, tell me a little bit about your company. What exactly do you do?

DAN FRIEBERG: We take agronomic data, help growers with agronomic data that they’re collecting to provide analytics and economics with farm finance. Then, that analytics turns into advice and an action plan for the following year. Most of what we do ends up with a variable-rate prescription that goes in a piece of equipment, whether it’s the grower’s equipment or it could be a retailer’s equipment.

DAVID WHITAKER: So, you’re basically working with the farm data. “Farm Data is the currency of the internet” is what I always tell Tanner. And you are taking that farm data, and then you are helping the farmer probably spend less money by doing variable rate throughout the field or making tough decisions to plant or not plant or certain things. That’s what I’m gathering. Is that correct?

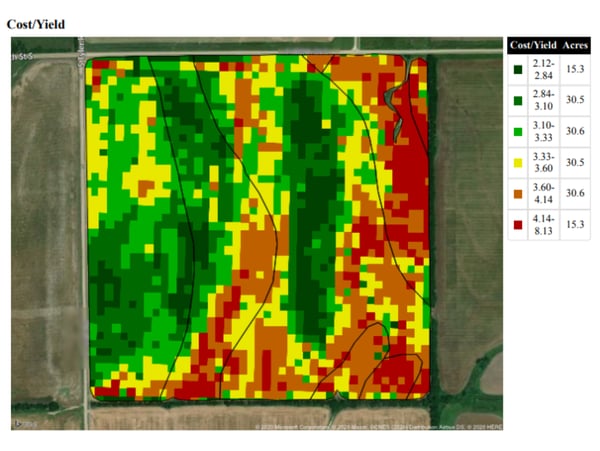

DAN FRIEBERG: I don’t think we ever save growers money. I think that’s one of the mistakes that a lot of people made in precision ag in the early years. We’re 20-some years into this, and a lot of the early messaging was around saving growers money. And I think that’s an unfulfilled promise. In the case of variable-rate lime, it is something that we do that saves the grower money on liming costs. But, most of the time, I think what we do is, rather than positioning it as saving the grower money, it’s about investing within parts of fields to get a higher return. So, instead of treating the whole field as though it’s the same, it’s about identifying areas that are capable of producing more and more efficiently. And then in other areas, it could be that that’s where you save them money because it just doesn’t make sense to continue to invest.

TANNER WINTERHOF: I grabbed it right off the website that Premier Crop was established in 1999. And what it says right there is this: “They enable the growers to think deeper about their data.” So, what I grabbed from that is using that variable-rate technology. The way to make that pay is not necessarily saving money but maybe reallocating those input dollars to site-specific areas, to where you could probably get a better return on your investment than where they might’ve just been blanketly broadcasted.

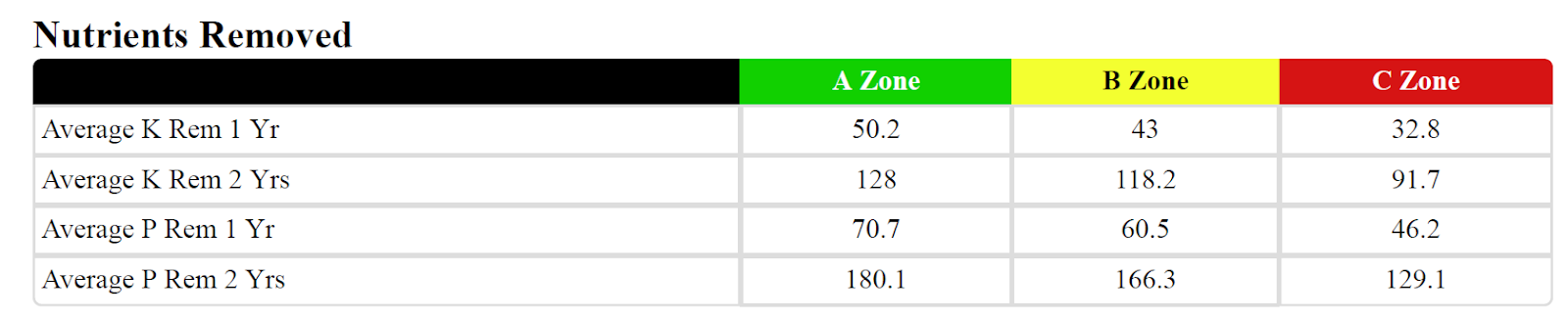

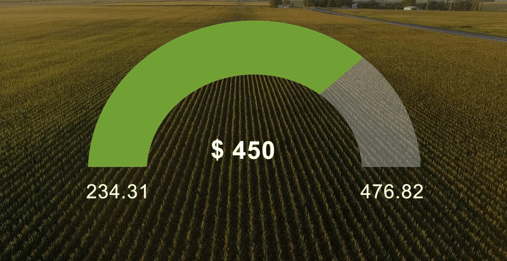

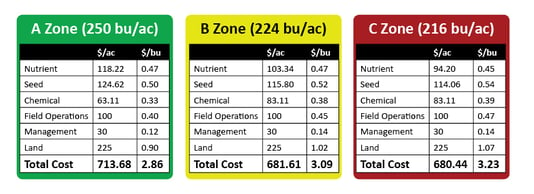

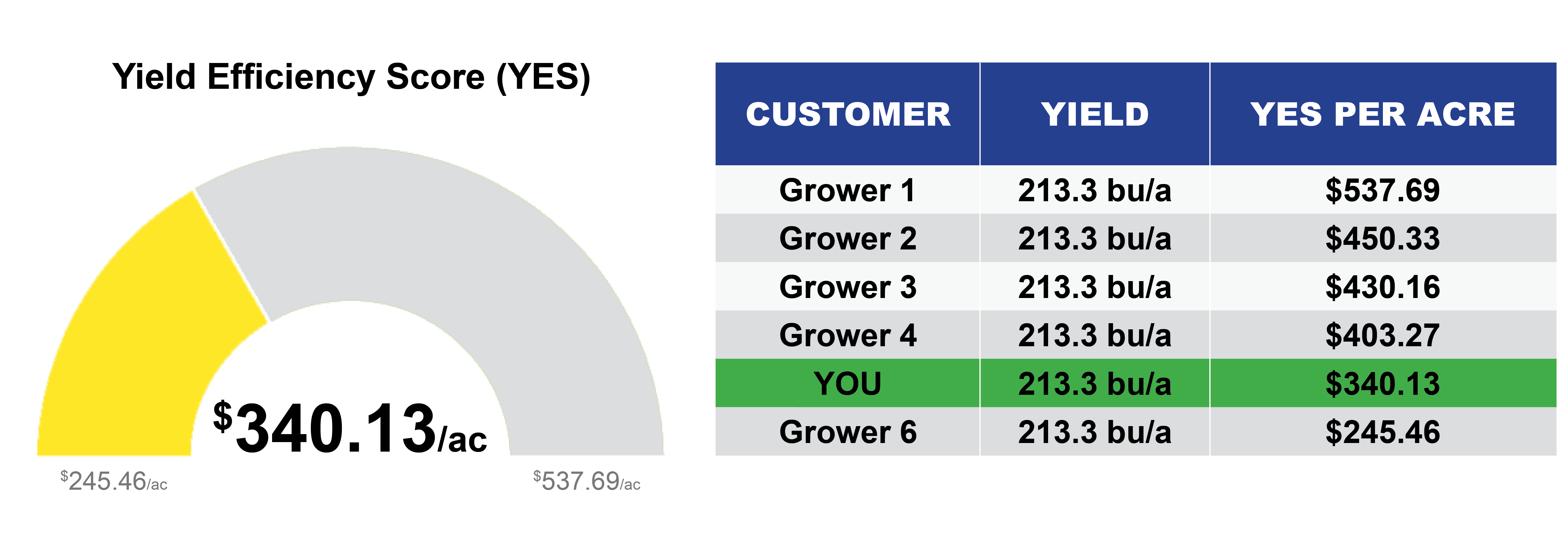

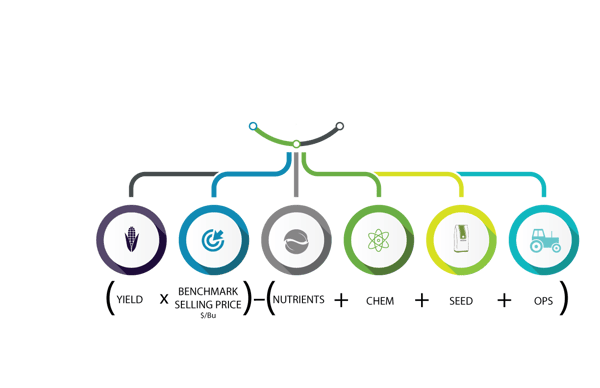

DAN FRIEBERG: Yep, I think that’s exactly right. I think maybe the other thing that we do differently is we have the ability to combine agronomics and economics. Right now, it’s really difficult to make money in a lot of areas. If we’re spending more in one part of the field, we’re able to actually tie the cost, the added costs that we’re investing in that part of the field, to the analysis. So, at the end of the year, we’re able to really deliver what we’re branding as a yield efficiency score, which is just dollar-per-acre return to land and management. For us, it’s about what’s been missing. We think there’s too much focus on just agronomics and not economics. I think right now, especially growers, they appreciate the focus on economics to help with farm finance. We like to say everything agronomic is economic.

DAVID WHITAKER: Gotcha. So, that’s a new term for me, the yield efficiency score that you have. Tell me a little bit more. Is it 100 is the best and zero is the worst, or how does your scoring system work?

DAN FRIEBERG: No, it’s really just dollar-per-acre return to land and management.

DAVID WHITAKER: Okay.

DAN FRIEBERG: It’s yield, and yield is tracked, obviously, with the yield monitor, a calibrated yield monitor. So, it’s yield at a benchmark selling price that the grower gets to set minus what they spent on nutrients, seed, crop protection and field operations. It’s kind of what’s left over. When a grower sees a yield efficiency score of $400, and they know they got $275 in land cost, then they immediately understand what’s left, the return to them for farm management.

TANNER WINTERHOF: So, if we’ve got a listener here who hasn’t been using variable-rate technology before as part of their operation, is that a large hurdle to overcome? Or do they pretty much have the technology on most of these farms to be able to implement that?

DAN FRIEBERG: Tanner, I think if $7 corn did anything for us, it was that there was a lot of investment in new technology in the cab. When we had that run-up in prices and in profitability, growers put a lot and they invested heavily in upgrading planters. In the process of what happened during that time period, there’s a lot of technology in the cab, but there’s a lot of growers who aren’t necessarily using farm data to the full advantage. They have the technology. They have the ability to do it. They haven’t started because they don’t know how, and they’re looking for solutions.

DAVID WHITAKER: You said $7 corn. A lot of people updated their equipment there. But, for our newbie farmer that’s out there, or even somebody that’s been doing it, if they’re in an older combine, whatever it may be, and they decide they want to upgrade and be able to use your systems, is there a minimum-like entry? Something that they’re going to need for farm equipment?

DAN FRIEBERG: For us, we use the yield monitor as a way of measuring, measuring whether what we did was the right thing.

DAVID WHITAKER: Do they have to have a WAAS GPS or a certain sub-inch or anything there?

DAN FRIEBERG: No, just a GPS, a yield monitor with a GPS receiver.

DAVID WHITAKER: Okay, fair enough.

TANNER WINTERHOF: Pretty simple to get in there. So, Premier Crop Systems really allows that farmer to really get the investment that they put into that technology and put it to work. You guys can really work with them to use the existing equipment that they have to their full potential. One of the other things that I had come across when I was reading is it really keeps that farmer from farming on averages. You really come down and do check blocks and break that field out into, I call them, profit zones, but maybe you have a different term. Could you explain what you do when you break a farm down?

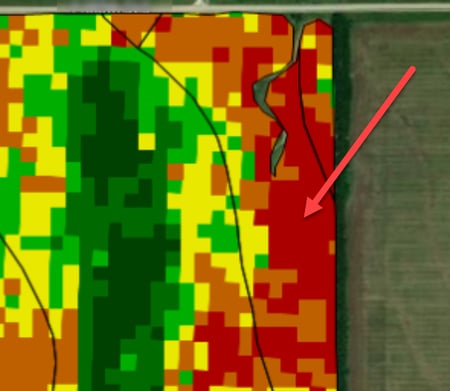

DAN FRIEBERG: Yeah, a lot of times that is what we do. We just try to identify, whether it’s management zones. We’re bringing a new version of that, which is performance zones, but it’s really trying to identify like-agronomic environments or unique agronomic environments within fields. It’s very much not treating it all like it’s the same. Tanner, within every field, growers will tell you there’s a sweet spot.

TANNER WINTERHOF: Yeah.

DAN FRIEBERG: Every grower who’s had a yield monitor has seen 80-90 bushel beans. They’ve seen greater than 100 bushel beans, and they just wish they could figure out what it was about that spot that made it so great. And that’s kind of what we try to help them do, identify those really high-yielding sweet spots, and a lot of times those are the ones that will respond the most to additional input investment. And then, conversely, there are areas that just don’t yield as consistently, and we try to solve the problem of whatever it is. We try to use farm data to help coach them on whatever those areas are. You’re in Huxley, and there’s a lot of potholes. There’s that north-central Iowa area. There are low areas. In wet years, they drown out. In dry years, they’re the highest yielding. They tend to be organic matter rich and nutrient rich because of all the years that they didn’t produce a crop. So, they’ll do great. They’ll do great in a dry year, but a lot of times we don’t invest near as much in inputs in those areas.

TANNER WINTERHOF: Yeah, take advantage of the resources that we have there.

DAN FRIEBERG: Tanner, the time is right, but it is tight on the farm. It’s really difficult to make money. That’s why farm finance and combining agronomics and economics is so important.

TANNER WINTERHOF: Yeah, it is.

DAN FRIEBERG: We have growers who tell us that some of this economic stuff we’re helping them with is what’s helping them convince their lender to give them the full operating line. So, we’re all about helping growers step up their game, and we know how difficult it is on everybody’s part.

TANNER WINTERHOF: It is.

DAN FRIEBERG: You guys don’t remember. I lived through the farm crisis of the 80s, and I was helping growers get financing. It was a dark and ugly time.

TANNER WINTERHOF: One of the things that I’ve noticed in the financing industry is that we have had more people utilizing creative financing methods, combining the dealer financing on their seed, getting some chem finance through their supplier, rather than getting their full operating through the bank. And part of that is our fault. We do get a little bit more conservative if we don’t have accurate records. So, I could see where Premier Crop Systems is valuable. And the fact that you can show me that, “Hey, we’ve got a plan. If mother nature cooperates halfway, we’re going to be able to put this plan to work and get us at least a crop that we can sell.”

DAN FRIEBERG: You guys know it because you’re interacting with growers. It’s a really high-stress time. When you see the farm suicide rate spiking, it’s reminiscent of just all the stress that’s going on with a lot of operations.

TANNER WINTERHOF: So, have you been advising any of your clients on what to do after the crop insurance adjuster shows up? Are you able to kind of help with a profitability calculation based upon what they’re learning after the derecho?

DAN FRIEBERG: Yeah, I mean it’s going to be difficult, like Corey will tell you. It’s going to be really difficult to get great data when you’re harvesting down corn. It really makes it difficult to have as much confidence in the data. It’s a struggle that way. Tanner, we’re right in the middle of it already because we’re starting to get ready for fall fertilizer prescriptions. If you’re not harvesting a crop, you’ve got nutrients that are in that crop that are going to get returned. So, you’re factoring that into your nutrient investment for next year, and so people are going to spend less on nutrients probably. But you’re trying to make sure you don’t short yourself in an area where you really need fertilizer manure to make it pay. It’s already started.

TANNER WINTERHOF: I’ve already heard guys talking that they might not be able to do as much corn on corn as they wanted to for fear of a volunteer coming up. Yeah, a lot of things are up in the air. I just got off the phone with a commodities broker who stated he’s got clients that just don’t know what to do. They’re in a limbo, waiting for the adjuster to show up, waiting for crops to dry down, waiting to find out what their options are.

DAVID WHITAKER: It’s an emotional roller coaster.

TANNER WINTERHOF: Yeah, any type of advice that they can get from a trusted advisor will go a long way.

DAVID WHITAKER: Yeah, it makes for an interesting year.

TANNER WINTERHOF: Well, Dan, I really thank you for joining us. I’m going to summarize real quick, and then let me know if we missed anything or if you want to share anything else. But we’ve got Dan Frieberg with Premier Crop Systems on the phone today, helping us out with our “What’s Working in Ag” segment. The company, started in 1999, enables growers to think deeper and utilize their data to make better agronomic decisions from that detailed data itself. They put the technology investments that you’ve already got on your farm to work for you. They want to make sure that you don’t think about farming on the average. Get down to a profit zone by profit zone analyst and management style, and then make sure that if you have a farm that is set up to where variable rate can pay, that it is not necessarily, Dave, the concept of saving you money. It’s more allocating those resources into a better part of the field that might make you more on the profit side. How did I do, Dan?

DAN FRIEBERG: You did perfect.

RENEE HANSEN: Thanks for listening to the Premier Podcast, where everything agronomic is economic. Please subscribe, rate and review this podcast so we can continue to provide the best precision ag and analytic results for you. And to learn more about Premier Crop, visit our blog at premiercrop.com.