Today we are talking with Dan and Darren about how to manage what you measure when it comes to your farm operation. Topics covered include ever changing complexities in the field, monitoring your return to land and management, and how to simplify your data to understand it better.

About Darren: CEO and President of Premier Crop. Fehr joined Premier Crop in 2018 and has successfully led the company in significant growth over the last two years. His passion for mentoring, leading and growing the business will be instrumental in the future of Premier Crop.

About Dan: Founder and current VP of Technical Services. Since founding PCS in 1999, Dan has witnessed many changes and transitions in the ag data industry.

If you are enjoying the show, tweet us using #PremierPodcast.

DARREN FEHR: We come across a lot of people who have a very small or narrow group of metrics that they’re measuring, and, consequently, the question that comes back to us often is: how do I improve my performance? So, let’s start here, Dan. Defining success is a very important first step. How has the definition of success evolved over time with the farmers that you have worked with?

DAN FRIEBERG: In general, growers get that, in order to drive higher profitability, they need to drive higher yields. So, they understand that higher yields are key, and the reason that’s the case is because row-crop farming is a high fixed-cost business. If you think about before you plant a crop, most of your machinery investment is locked in. The fuel and the labor to actually make passes across the field is variable. Obviously, land cost, whether you own it or rent it, is, by far, the biggest fixed cost. There’s a lot of other costs: family living, health insurance and all those things.

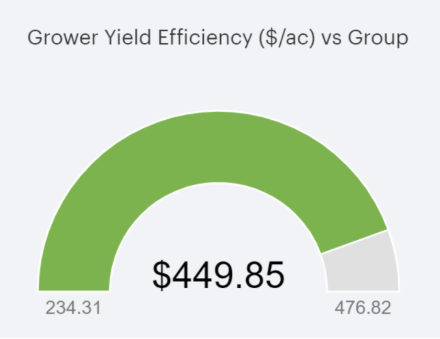

Whether you produce 100-bushel corn, or 200-bushel corn, or 50-bushel wheat, or 80-bushel wheat, it doesn’t matter. You still have a bunch of fixed costs. Producing more bushels is the only way to drive your cost down. So, yield has become the surrogate for profitability, but we know better. We know that all yield isn’t created equal. It’s really not about yield. It’s about how efficiently we produce yield and how many dollars do we return to land and management.

DARREN FEHR: We started talking about this topic, I don’t know, 18 months ago, 24 months ago. Now, economics is a really big part of the conversation. When people think about how they drive success, what are some of the big barriers to actually uncovering this idea that I know what my profitability is, or my return on investment? This ROI thing gets thrown around really easily, but this isn’t easy to get to. What advice do you have for farmers to really be proactive in getting to understand how much they get back for every dollar they spend?

DAN FRIEBERG: It is really complex. I had a friend, a professor at Iowa State, who said real-world agronomy isn’t rocket science. It’s way more complex than rocket science. His point is we put somebody on the moon with what wouldn’t be the equivalent of a PC now, or a laptop now. He’s basically saying that real-world agronomy is just super complex because it’s this interaction of all these different biological factors, including the weather and soils and fertility and seeds and genetics. If you appreciate that agronomy is incredibly complex, and you add economics to that, then everything agronomic is economic.

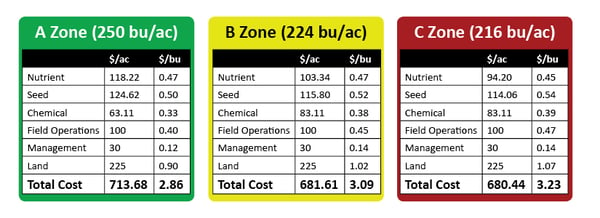

The reason we make the agronomic decisions we do is because we get that there’s an economic impact to them. When you add all those pieces together, there are lots of complexity to deal with. What we argue is that agronomic-economic complexity is very spatial, meaning it’s changing within fields. There are parts of fields that are just begging to be managed at a higher level. And there are parts of fields that are sending signals, like, you just need to quit wasting money here. You need to change to what is successful in each part of the field.

DARREN FEHR: Dan, as the industry’s evolved, and we’ve got this many billions of dollars of venture capital funding come in towards a variety of different ag tech startups, we have this division happening. We have precision ag that’s more agronomy focused, and we have farm management information systems, which is arguably more economic focused, maybe less agronomic and more economic. Why is there this division happening, where people are having to choose: am I going to focus on subfield agronomy? Or am I going to focus on field-level economics?

DAN FRIEBERG: Of course, our answer is you don’t have to choose. That’s what we’re about. We are all about combining those pieces together. Our solution is not one or the other. It’s both.

With Premier, this is 22 years, maybe 23 crop seasons. I’m convinced that the reason every grower doesn’t do what we do — and this is not just us, this is not just Premier — is the precision. If you put every company that has any kind of a precision ag offering, and that includes a lot of major companies, like really big companies, there’s a whole bunch of offerings. But the reason every grower doesn’t do what we do is we haven’t shown, year after year, that it pays. It’s almost that simple. If we show growers that it pays every year, they’ll do it. There’s always an adoption curve, but, eventually, everybody gets on the bus because it’s just a matter of proving that it pays.

That’s why, for us, this push to tie economics to agronomics is such a big deal. That’s what we’re doing year over year. We’re proving that it pays. If we advocate or advise the grower to spend more money in the best part of the field, at the end of the year, it’s not a “trust me” it works. We’re providing the dollars-and-cents analysis to show that they got a higher return. So, to your ROI message, that’s exactly what we’re doing. A lot of times, they’re spending 30 to 50 dollars an acre more on inputs in the best part of the field, but we’re generating an additional 80-dollar return to land and management beyond that input spend.

DARREN FEHR: You’re saying that there’s that much money left on the table at the end of the day. Once people have an accurate view of precision economics at the subfield level, there is that much money left on the table?

DAN FRIEBERG: There is. The more we get people excited about doing this, the more we’re going to be able to stretch those numbers even higher. There is no doubt we need to continue to push higher yields. The times right now demand that you scrutinize every dollar you spend to get the higher return. We used to have a slump in commodity prices. It begs that we just have to be keen on how we spend every input and every input dollar to get higher returns.

DARREN FEHR: So, in this environment, what we’re facing, with a significant cash issue at the farm gate, this isn’t about cutting costs. This is about managing costs, so that every dollar we spend stretches as far as possible.

DAN FRIEBERG: You may cut costs in some parts of some fields. It would be a false promise to suggest that you’re not going to spend whatever you save, that you’re not going to spend extra in the best part of the field. The point is we have the ability to prove and to deliver a report card on every field that says it paid. It paid better than if we flat-rated it and pretended it was all the same.

DARREN FEHR: So, we started off with how you can’t manage what you don’t measure. Dan, what are the metrics? What should farmers be measuring?

DAN FRIEBERG: Everything. That’s what makes it so complex. We talked about 400 layers of data at a subfield level, and people just think that we’re crazy stupid for handling the complexity of all those data layers, but that’s reality. So, the idea is it’s not one thing that matters. It’s the combination of a whole bunch of things that matter, and it changes. It changes within fields, so what matters is different within different parts of the field.

Darren, everybody in the United States can bring in digitized soils. Digitized soils means we get soil type and texture and slope and drainage class and things like that. You can bring in soils layers, which is a great starting place. In our case, we have a lot of spatial soil sampling, meaning zone or grid sampled. Instead of just doing one sample that represents the entire field, you’re capturing differences, which means you’re capturing differences in organic matter and pH and fertility. There could be a couple dozen layers captured that way.

We capture as-applied fertility. That’s more complex than people think because there’s a lot of growers that would put nitrogen on five different ways. There would be some with the phosphorus, some weed and feed, some primary N goes on or side dress or manure or starter. We capture rate, source and cost, so those are all sortable data layers that can be analyzed. We get probably 15 layers off the planting file: its population, density, seeds and things like hybrid and variety. There are hundreds of layers that aren’t necessarily captured on a monitor that really matter.

Manure would be an example. There are a lot of manure applications that really have a huge impact, both agronomically and economically. There’s a lot of input capturing the real cost associated with all this, too. It’s just a lot of detail, but that’s what we do because we think that’s what’s most meaningful.

DAN FRIEBERG: Darren, you said that you can’t manage what you don’t measure. That was a Peter Drucker quote. I would recognize the name, but the younger generation doesn’t even recognize Peter Drucker’s name. He’s a management guru, but people have added on to that Drucker statement. One of the add-ons to the Drucker statement is: things you measure tend to improve. So, if you don’t measure it, does it have any chance of improving? It just really goes to being intentional and having a goal. That’s what we do with growers when we’re interacting with growers.

Every year, there’s a goal-setting discussion about: how are we going to measure success? With some growers, they want to drive yield efficiency. They want to drive higher returns, so that they can hire some help and their family life can improve. They can have more time with the family because they’re able to afford hired labor. Others want to expand their operation. Everybody’s got slightly different goals, but, usually, it comes down to: they’re business people, and they want to generate more returns or hold their operating capital in check.

DARREN FEHR: The reality is the definition of success is different for everyone, but the other reality is that profitability matters. In having a business, whether it’s farming or anything else, everybody’s trying to make some money. Measuring the right parts to drive operational growth and profitable growth is really important. So, we’re going to talk about trying to stay ahead of the game, trying to plan before you buy, as opposed to buying and then trying to plan where you place the input. Stay tuned for that. Dan, thanks a lot for being with us this morning and talking about how you can’t manage what you don’t measure and driving higher yield efficiency.

______________________________________________________________________________________________________________

Continue to listen to the Premier Podcast, where everything agronomic is economic. Please subscribe, rate and review this podcast, so we can continue to provide the best precision ag and analytic results for you.

Free Resources:

- For more helpful tips and insight on all things data and agriculture, visit our blog at http://info.premiercrop.com/blog

- Curious about precision ag? Download our 5 Steps to Getting Started Guide: http://info.premiercrop.com/5-steps-guide

- Ready to cut through the bull? Download our No Bull Guide to Precision Ag: http://info.premiercrop.com/field-profitability-guide

- Podcast provided by Premier Crop Systems. Learn more about us at https://www.premiercrop.com